Application of computer vision techniques to estimate surface roughness on wood-based sanded workpieces

➤ Download Accepted Manuscript

Highlights

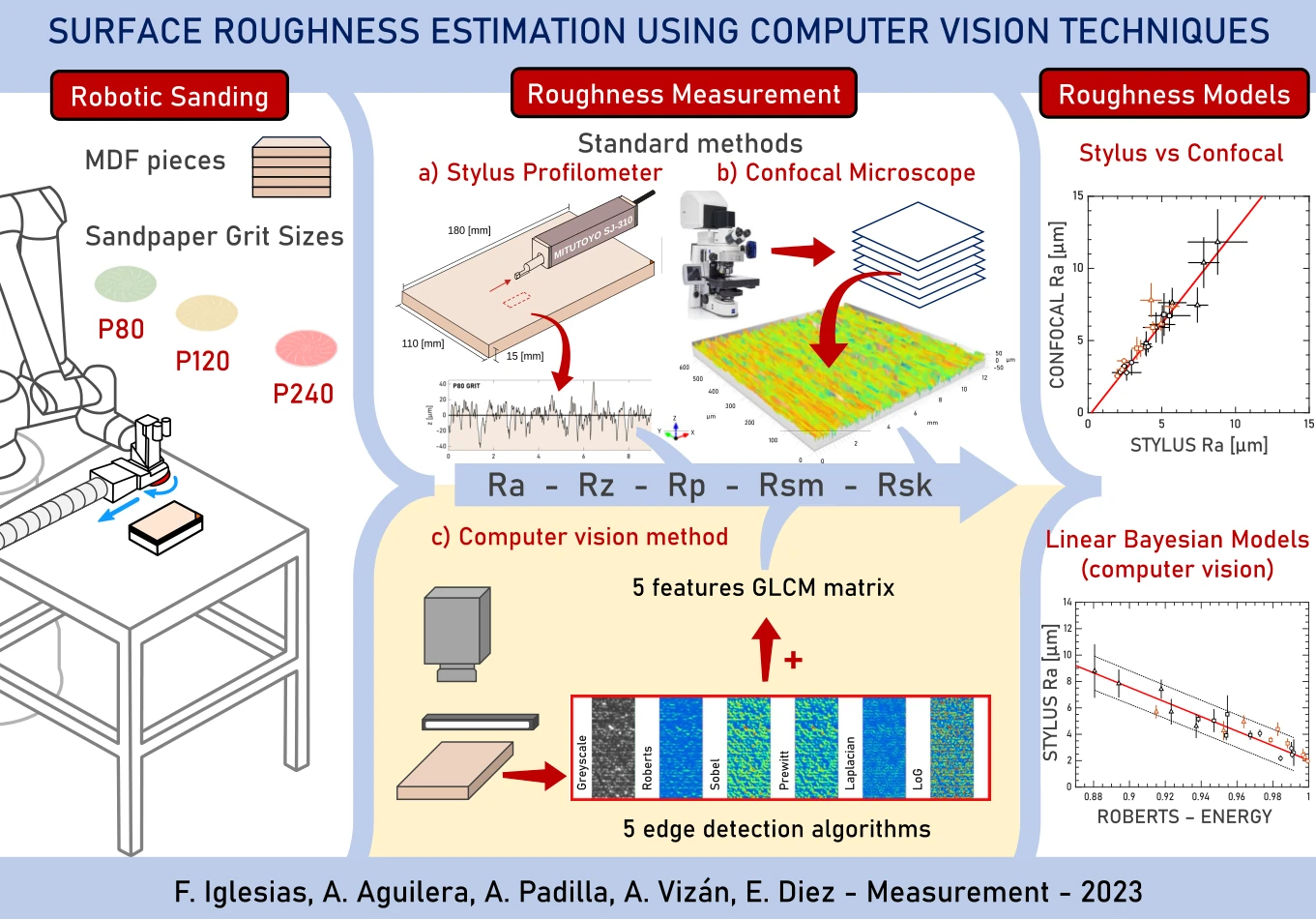

- A novel artificial vision method for estimating roughness in wood-based products.

- Features are extracted from surface photographs enhanced with edge detection.

- Bayesian models relate image features and surface roughness with high correlation.

- Computer vision is compared to stylus and confocal microscope measurements.

- The best results are obtained with the Roberts algorithm and Energy feature.

Abstract

In the wood industry, surface inspection post-sanding is critical during the final production stages. This inspection relies on subjective assessments made by operators due to the challenges of adapting traditional measuring techniques to industrial environments. This study introduces an innovative artificial vision approach for the in-line inspection of surface roughness applied to wood and wood-based products in highly automated manufacturing systems. The procedure is based on extracting features from the grey-level co-occurrence matrix in images processed with edge-detection algorithms. Images are derived from photographs of sanded medium-density fibreboard, and models predicting surface roughness were formulated and compared with direct measurements using a stylus profilometer and a confocal microscope. Results showed that the most effective algorithm-feature combination was Roberts and Uniformity of Energy, with consistent performance for different roughness parameters. This approach can improve quality control and extend to a broader range of materials and applications.

Graphical Abstract

Please cite this article as:

F. Iglesias, A. Aguilera, A. Padilla, A. Vizan, E. Diez, Application of computer vision techniques to estimate surface roughness on wood-based sanded workpieces, Measurement (2024), doi: https://doi.org/10.1016/j.measurement.2023.113917